Engraving knowledge

Lexicon

In the world of engraving technology and its associated manufacturing processes, there is a plethora of terms and concepts that are central to professionals in this industry. From traditional methods like etching and annealing to modern techniques like Computer-Aided Design (CAD) and Computerized Numerical Control (CNC), the spectrum of specialized terminology used in this field is vast. Each of these terms contributes to the rich diversity of manufacturing processes that are essential in the modern production landscape.

Engraving itself, as an art form that serves both aesthetic and functional purposes, has a long history and is constantly evolving. It is applied in jewelry making, tooling, medal and coin minting, and many other areas where precise and enduring markings are required. Modern technologies such as laser engraving and electrochemical etching have expanded the possibilities in this field, allowing for incredibly precise work.

Furthermore, materials and their specific properties, such as hardness, density, and heat treatment, play a crucial role in engraving technology. These material characteristics determine how a material behaves under various processing conditions and influence the selection of the appropriate engraving technique. Knowledge of raw materials, alloys, and the proper choice of tools is essential to achieve high-quality results.

In this context, it is important to have a comprehensive understanding of the various terms and methods used in engraving technology and related processes. A lexicon that explains all these aspects in detail serves as a valuable reference for professionals and enthusiasts alike to deepen their knowledge and refine their skills.

- Alloy: A metallic material consisting of two or more elements, with at least one being a metal. Alloys are created to enhance the properties of the base metal, such as strength, corrosion resistance, or hardness.

- Bandstamps: A special tool used in bookbinding to impress decorative lines or bands onto book covers. These stamps can have different patterns and are often used to enhance the visual appeal of books.

- Base: In heraldry, the lower part of a coat of arms, often filled with specific symbols or patterns representing families, cities, or organizations.

- Blind embossing stamp: A tool used for blind embossing, where a design, text, or pattern is embossed on materials such as leather, paper, or cardboard without ink. The resulting embossment creates a raised or recessed pattern perceived through the interplay of shadow and texture.

- Brand logo: A graphic symbol representing a company and often a central element of its corporate identity. In engraving, the company logo is frequently engraved on products, promotional materials, or corporate buildings to promote brand recognition.

- CAD (Computer-Aided Design): A technology tool used to design and model products precisely, commonly employed in engineering, architecture, and design fields. CAD enables the creation of complex shapes and structures in a digital format, enhancing planning and visualization.

- Carbide: A class of materials consisting of ceramic particles (mostly carbides, such as tungsten carbide) embedded in a metallic binder (often cobalt). Carbide tools are valued for their high wear resistance and cutting ability.

- Coat of Arms: A heraldic design on a shield or shield-shaped emblem representing a person, family, or organization. Coats of arms are deeply rooted in tradition and are commonly used in personalized engravings.

- Coin Minting: The process of producing coins where metal plates are pressed between two matrices to create a detailed design on both sides of the coin.

- Cold Foil Stamping: A printing process where a metallic foil is pressed onto a substrate without heat, typically used to give packaging or labels a high-quality, metallic appearance.

- Colorway: A term used in printing to describe different color versions of a printed product, often used in the production of collectibles such as stamps or banknotes.

- Computerized Numerical Control (CNC): An automation technology where machine tools are controlled by computer programs. CNC is utilized in the manufacturing industry to process, cut, or engrave workpieces with high precision.

- Corporate Identity: A term describing the visual appearance of a company, including its logo, design, uniforms, and other visual elements that help maintain a consistent and recognizable image of the company.

- Cutting speed: The speed at which a cutting tool moves through the material. An optimal cutting speed is crucial for efficient and precise cuts, especially in CNC machining.

- Density (Physics): A measure of mass per unit volume of a material. In engraving and other manufacturing processes, density is crucial for determining how different materials can be processed and how they behave under load.

- Dielektrikum: A non-conductive substance that supports electric fields without conducting electricity itself. In electrical discharge machining (EDM), a dielectric is used to enable sparks between the electrode and the workpiece without a current flowing through the medium itself.

- DIN 1451: A typeface standard originally developed by the German standards organization for traffic signs, technical labeling, and other applications. In engraving, this clear, highly legible typeface is frequently used for industrial labeling.

- Drum Galvanizing: A process in electroplating where small parts are placed into a rotating drum containing an electrolyte solution. This allows for an even coating of the parts.

- Electrolyte: A liquid or gel containing ions capable of conducting electricity. In electroplating and electrochemical etching, an electrolyte is used to transport metal ions and deposit or remove a metal layer on a substrate.

- Electroplating: A process for coating a metal object with another metal through electroplating. The object to be coated is immersed in a solution containing the coating metal in ionic form and is connected as the cathode, while an anode made of the coating metal is also immersed in the solution. This process is often used to improve corrosion resistance or for aesthetics (e.g., gold plating).

- Engraving: A technique where material is removed from a surface to create text, patterns, or images. Engravings can be made in metal, wood, glass, or other materials for decorative or functional purposes. Modern engraving methods include laser engraving, mechanical engraving, and etching processes.

- Embossing: A printing process where a design or text is pressed into a material, creating a raised or recessed appearance. This process is often used for high-quality business papers, invitations, and book covers.

- Etching: A process for creating patterns or images on metal, glass, or plastic surfaces through chemical or electrochemical corrosion. Etching is used in microelectronics, art, and jewelry making to produce fine lines and detailed designs that would otherwise be difficult to achieve.

- Flexographic: A form of high-pressure printing commonly used for packaging. Flexographic printing plates can be engraved to produce any desired image or pattern and use fast-drying inks.

- Font size (DTP system in pt unit): The size of letters and characters in a document, measured in points (pt). One point equals 1/72 of an inch.

- Hardness: A measure of a material’s resistance to deformation or penetration. In engraving, the hardness of the tool and the material being engraved are crucial for the final result.

- Hardening (steel): A heat treatment process that increases the hardness and strength of steel. The steel is heated to a high temperature and then rapidly cooled (quenched) to change its metallurgical structure.

- Heat Treatment: A controlled process of heating and cooling metals to improve their physical and mechanical properties, such as hardness, toughness, and strength.

- Heraldry: The art and science of heraldry. Heraldry deals with the design, description, and use of coats of arms and other heraldic symbols.

- High-speed cutting (HSC): A manufacturing process that utilizes high spindle speeds and feed rates to efficiently remove metal and reduce production time.

- High-speed steel: A class of high-alloy steel known for its ability to handle high cutting speeds in metalworking without losing its hardness. Ideal for the production of cutting tools.

- Hot foil stamping: A printing process where heat and pressure are used to transfer a thin foil onto a substrate. This is often applied for decorative purposes on book covers, packaging, or greeting cards.

- Ligature (Typography): A connection of two or more letters into a single unit in a typeface, often used to enhance readability or for aesthetic purposes.

- Logo (Graphic): A graphical symbol or combination of letters representing an organization or product, commonly used in corporate communication and marketing.

- Logography: A method of writing where each word or concept is represented by a single symbol or character, as opposed to phonetic or alphabetical systems.

- Makrotypography: Involves the design and arrangement of text on a page or within a larger layout, including font selection, line spacing, and column width. Makrotypography plays an essential role in creating visually appealing and easily readable print and digital media.

- Matrix: A tool or mold used for making replicas through embossing, casting, or stamping. In coin minting, for example, the matrix is the embossed form used to transfer the design onto the blank.

- Medal: A usually round plaque or coin used as an award for achievement or as a memento. Medals are often made by pressing metal using specific matrices.

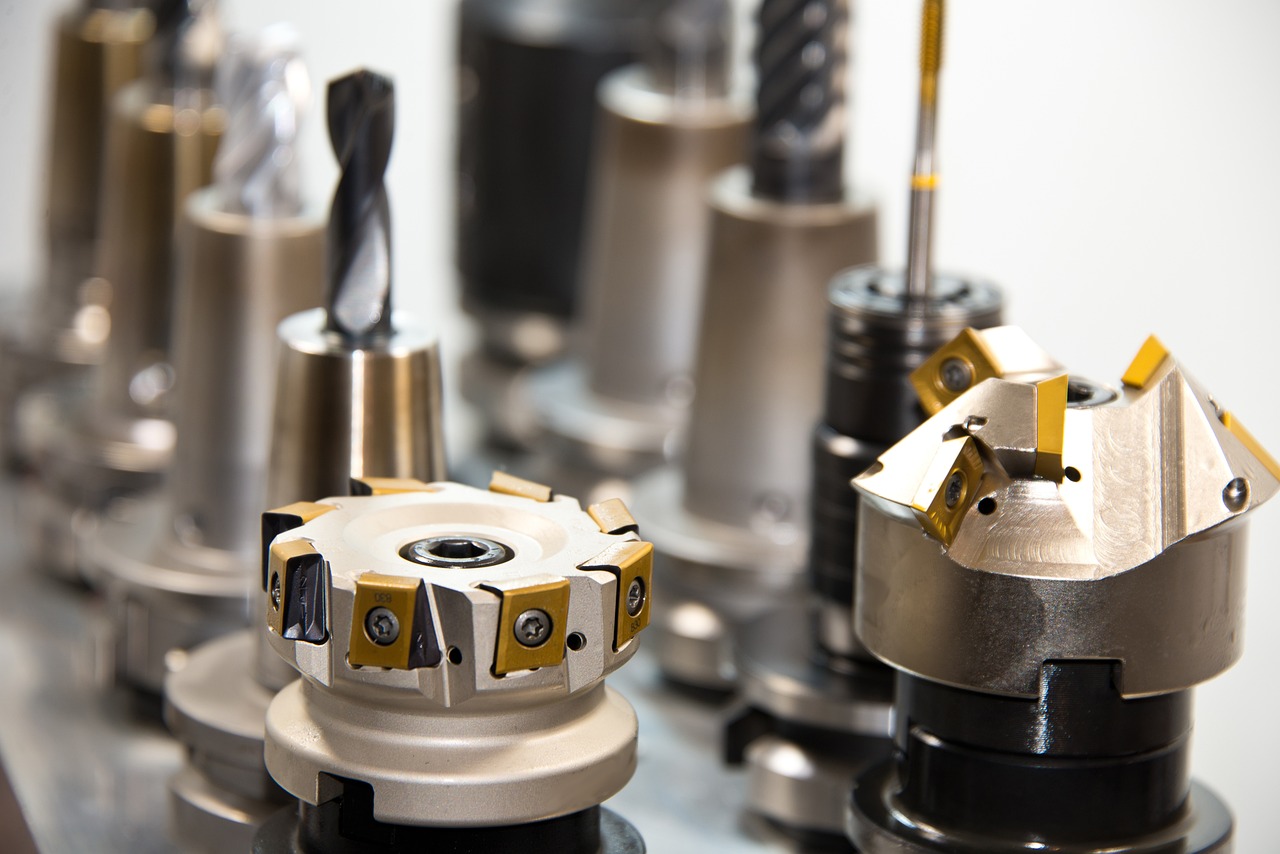

- Milling tool: A cutting tool used in lathes or milling machines to remove material from a workpiece. In engraving, special milling tools are used to create precise and detailed patterns and designs.

- Monogram: A graphical representation typically consisting of two or more interwoven letters used as a personal symbol or logo. Monograms are often engraved on personal items such as stationery, wedding invitations, or clothing.

- Obverse (Numismatics): Refers to the front side of a coin, medal, or other flat metallic object. The obverse often displays important symbolic motifs, portraits, or the main design and is often the more representative part of the object compared to the reverse (back side).

- Ornament: A decorative pattern or design often used in architecture, on everyday objects, or in art. In engraving, ornaments are used to adorn surfaces and enhance aesthetic values.

- Pagination stamp: A stamp used to print consecutive numbering on documents, often used in offices or document management.

- Patrize: The counterpart to the die, often a positively shaped tool that fits into the die. In coinage, the patrize is the top of the tool that impresses the design onto the coin blank.

- Pertinax: A hard, phenolic resin-soaked paper material used in the electronics industry and for die-cutting tools. Pertinax is known for its good insulation properties and mechanical strength.

- Petschaft: A seal stamp that carries a personal seal and is used to seal and authenticate documents. Traditionally, petschafts were made of metal and often had a handle.

- Plomb: A security seal made of metal or plastic used to verify that a container or package has not been opened since sealing.

- Printing Plate: A plate used in various printing processes such as offset and gravure printing. Printing plates are often made of metal or plastic and carry the image or text to be printed.

- Punching: The stamping of markings or symbols into a piece of metal, often to indicate the manufacturer, metal content, or place of origin. Punching is particularly common in the jewelry and silverware industries.

- Quenching and Tempering (Steel): A heat treatment process where steel is heated and then quenched, followed by tempering at a lower temperature. This enhances mechanical properties such as toughness and ductility.

- Raster graphic: A digital image format consisting of a grid of pixels, with each pixel having a specific color. Raster graphics are particularly useful for detailed images such as photographs but may suffer quality loss when scaled.

- Raster typography: A style of typography that uses pixels or dots to represent letters and characters, typically seen in digital displays and computer printing. This technique allows for clear and readable text to be displayed on screens.

- Relief printing: A printing process where the raised parts of a printing plate are inked and then pressed onto paper or another medium. This is one of the oldest printing techniques.

- Reverse (Numismatics): The backside of a coin, medal, or similar object, which often bears additional designs or information and serves as the counterpart to the obverse.

- Rotogravure: A printing process where the printing elements are recessed. Ink is deposited into the recesses and then transferred onto the paper. This method is particularly suitable for high-volume printing jobs such as magazines and catalogs.

- Semi-finished product: A prefabricated material or intermediate product that is further processed or refined to produce finished products. In manufacturing, semi-finished products are often used in the form of sheets, bars, tubes, or profiles.

- Seal: A stamp or other form of embossment used to authenticate or seal a document. Seals often bear a specific design or the emblem of an organization.

- Sealing wax: Wax used to seal letters and other documents. The wax is melted and then embossed with a seal stamp to ensure the document’s integrity.

- Sheet metal seal pliers: A tool used to seal sheet metal seals in security or identification applications. The pliers impress the metal in such a way that it fits around the closure mechanism of a package or container, securing it.

- Signet ring: A ring bearing the seal of a person or organization, traditionally pressed in wax or similar materials to seal documents.

- Signature: A unique mark or inscription of a person used for identification or to authenticate documents.

- Sinking erosion: A manufacturing process that uses an electrode shaped into the form of the desired cavity or pattern to remove material through electrical discharges. This is often used for complex or precise shapes.

- Soldering: A process where two or more metal parts are joined together by heating and melting a filler metal (solder). Soldering is commonly used in electronics and metalworking.

- Spark erosion: A manufacturing process that uses electrical discharges to shape or cut electrically conductive material. This process allows for the machining of complex shapes and hard materials that would be difficult to work with traditional cutting tools. Another term for electrical discharge machining, describing the use of electrical sparks for material removal, allowing for the creation of very fine details and complex geometries.

- Stamp punch: A tool used to imprint markings, numbers, or letters into a material through the action of striking. Stamp punches are commonly used in metalworking.

- Tempering: A thermal process aimed at improving the mechanical properties of hardened metal. During tempering, the metal is heated to a temperature below its critical transformation temperature and then cooled down in a controlled manner. This reduces the hardness slightly but increases toughness and ductility.

- Tool Edge: The part of a cutting tool that cuts the material. The tool edge must be sharp and made of a material that withstands wear from the material being cut.

- Tool life: The operating duration of a tool or machine before it needs to be replaced or serviced, often measured by the amount of processing it withstands without losing performance.

- Tool Steel: A class of carbon and alloy steels specifically designed for making tools that need to withstand heat and abrasion. These steels are commonly used in the manufacturing of cutting tools, dies, and punches.

- Tracking: The horizontal spacing between letters in a text. Proper tracking adjustment is important for the readability of text.

- Typography: The art and technique of arranging type, primarily for printed text. The goal is to optimize readability and achieve the desired visual effect.

- Uppercase: Capital letters used in typography to emphasize text or add aesthetic accents. They are often used for headings, logos, and other design elements.

- Vector Graphics: Graphics composed of paths defined by points (also known as nodes or control points), connected by lines and curves. Vector graphics are particularly valuable in the design and production industries as they can be scaled indefinitely without loss of quality.

- Welder’s stamp: A specialized tool used by welders to apply their identification markings on welds and other metalwork. This ensures traceability and quality assurance in manufacturing.

- Wire EDM (Electrical Discharge Machining): A manufacturing process that utilizes electrical discharges to precisely cut a conductive material. A metallic wire serves as an electrode, eroding the material along a pre-programmed path.

- Zincography: A printing process based on the use of zinc plates, similar to lithography but often used for more detailed and finer prints. Zincography is used in various applications such as book printing and commercial printing.