Modern and reliable

Our machinery fleet

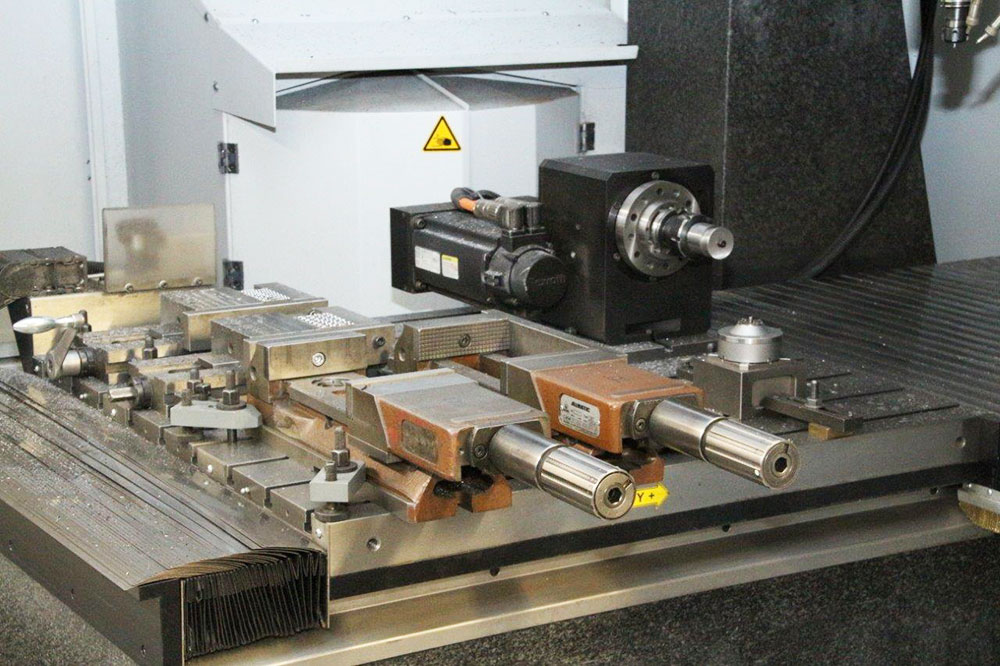

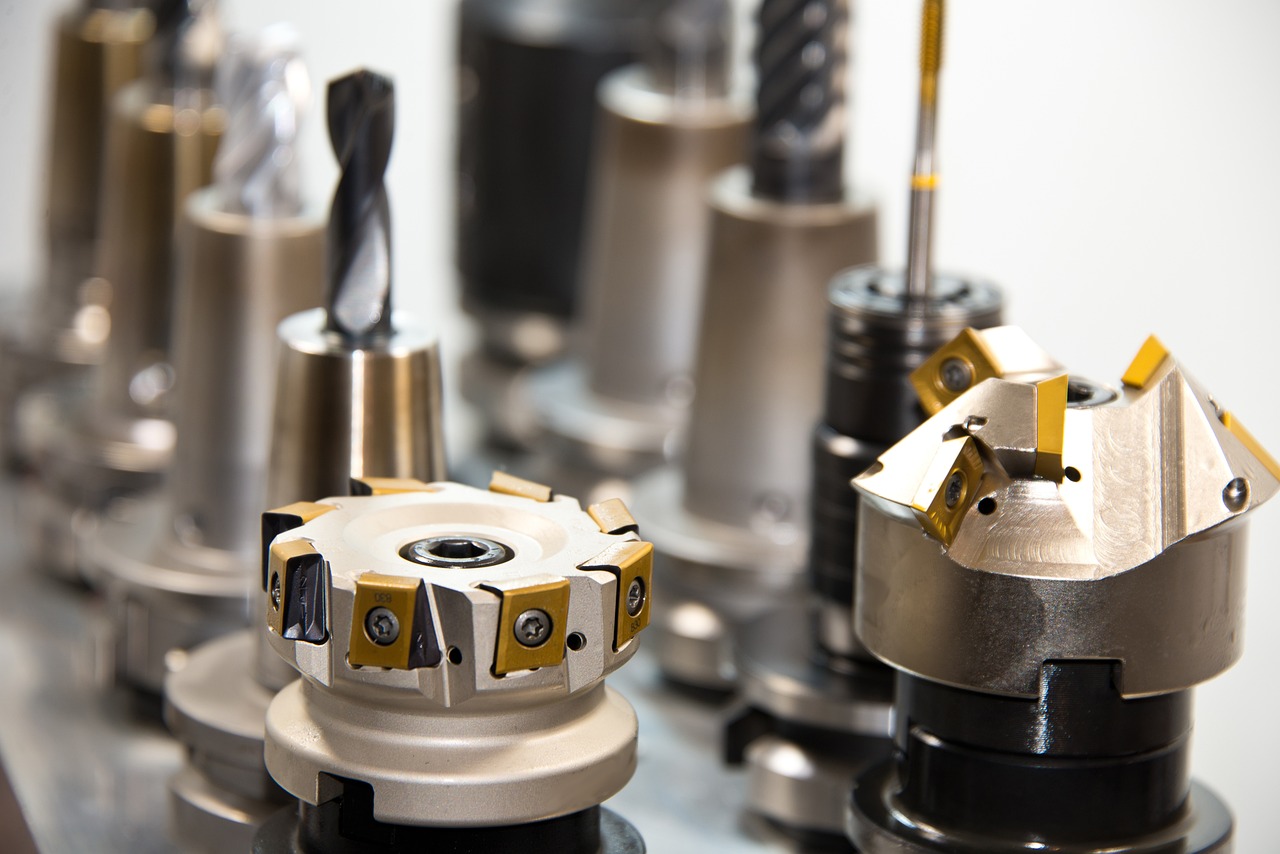

Perfect craftsmanship and a state-of-the-art machine park – that’s the secret to success at Jungjohann. Whether milling, engraving, or EDM, the precision of modern CNC technology alone is not a guarantee for convincing results. It is the profound material knowledge of Jungjohann’s engravers and their years of experience that ensure success. This expertise allows them to master every challenge with tailor-made accuracy, taking into account and optimally utilizing the nuances of each material.

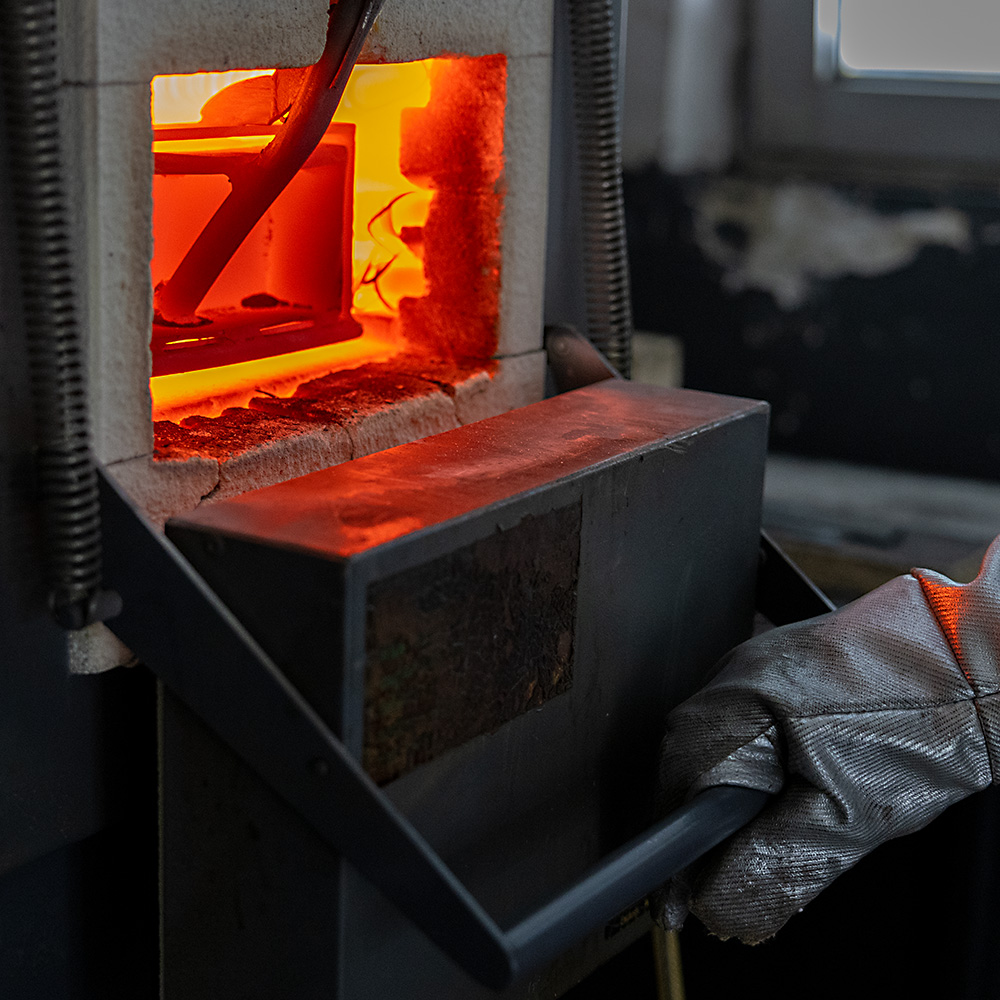

The in-house heat treatment facility, which is also suitable for powder metallurgical steels, shortens delivery times and enables the company to respond individually and quickly to special customer requests. Additionally, this facility offers the ability to precisely control heat treatment processes, significantly enhancing the quality and performance of the end products. This integrated control over the production process strengthens Jungjohann’s ability to deliver consistent and high-quality results while simultaneously increasing flexibility to innovate in response to market changes and customer requirements.

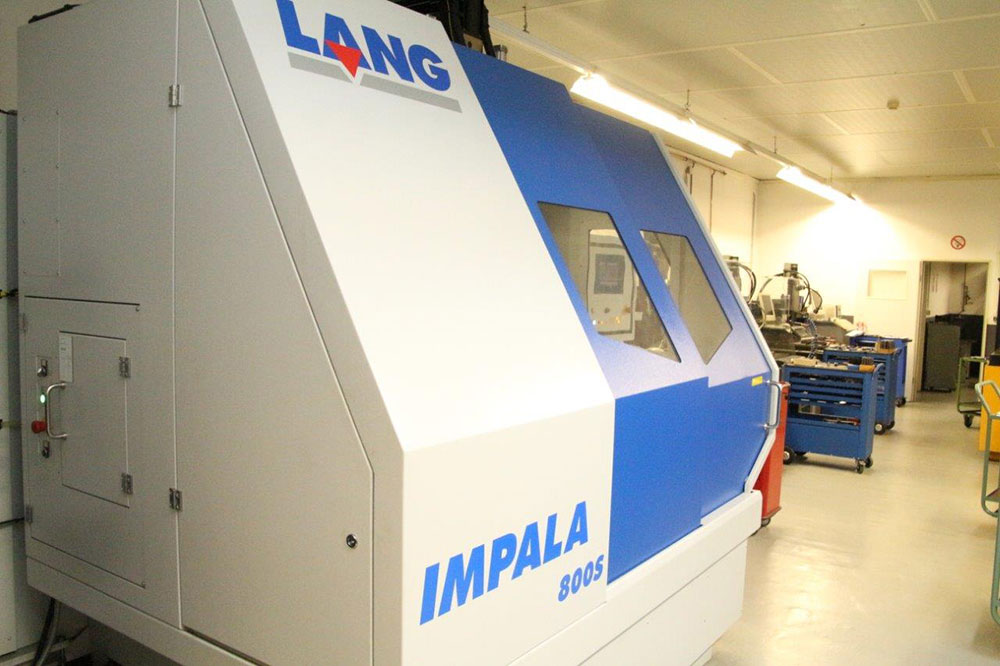

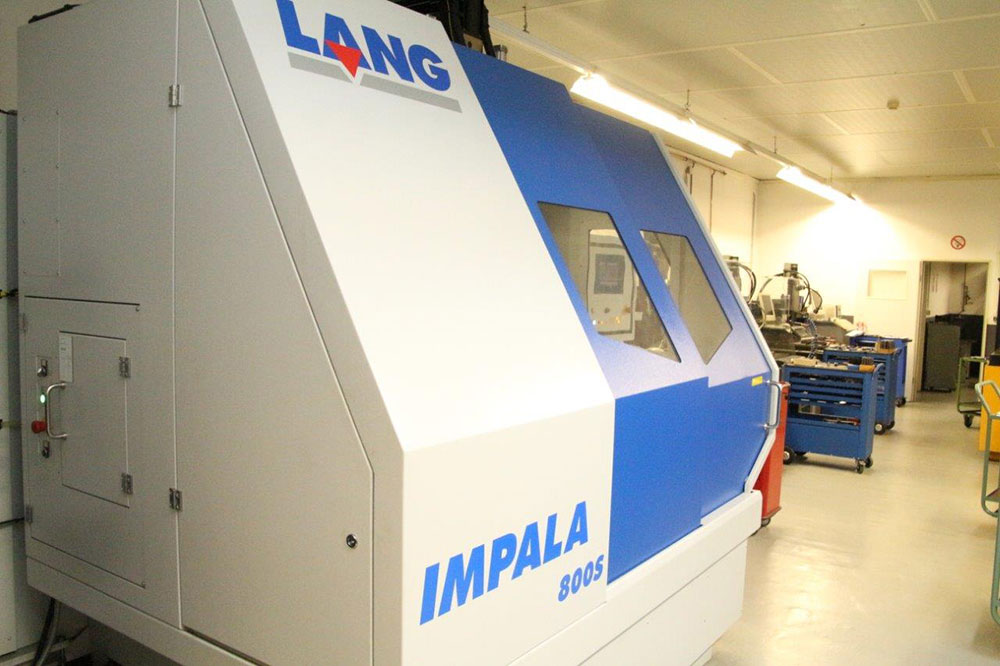

XXL machine for large applications

Engravings up to 800 x 800 mm

Jungjohann is raising the standards in the engraving industry with the Impala 800S, a revolutionary engraving machine that can precisely process workpieces up to the impressive dimensions of 800 x 800 mm. This remarkable capacity enables the execution of larger and more complex engraving tasks with unmatched accuracy and efficiency. Ideal for industrial applications, the Impala 800S allows for the machining of extensive metal plates, making it especially valuable for the production of machine stamps, hot foil stamps, and other industrial engraving tasks. The generous work surface of this machine is hard to match in the industry and enables the realization of large-format projects that go beyond standard sizes. This unique feature makes Jungjohann a preferred partner for companies that want to lead in the use of engraving technology. With the Impala 800S, our customers can expand their production limits, implement their creative visions without restrictions, and always rely on the proven quality and reliability of Jungjohann.

Excellence in every detail

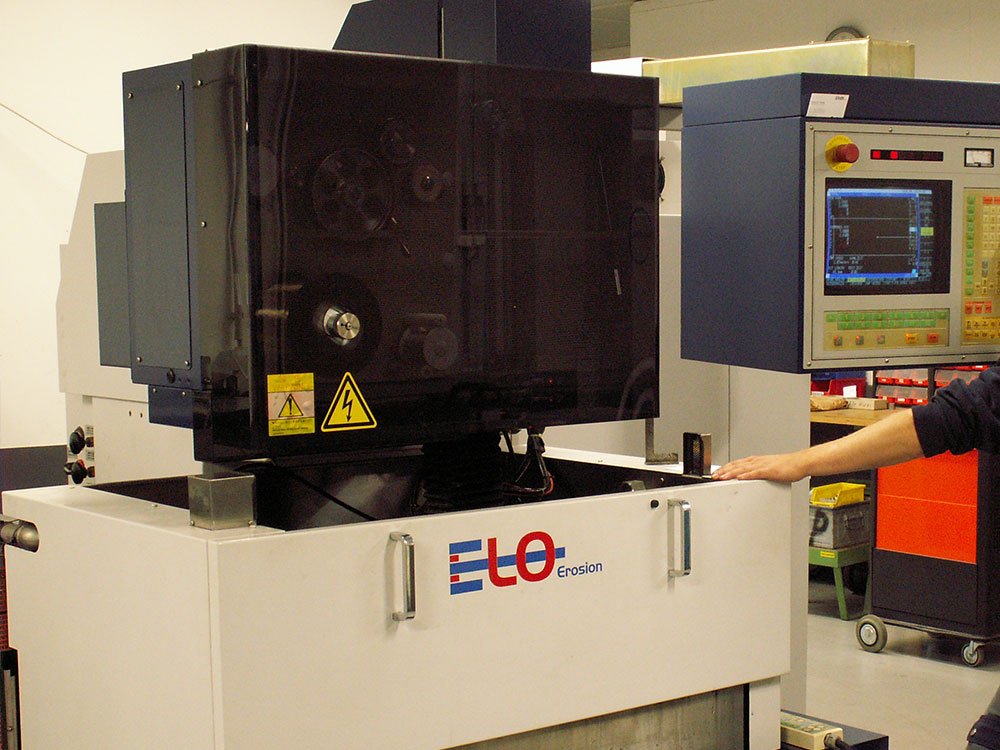

EDM machines for finest work

Jungjohann utilizes Fanuc EDM machines to ensure precise and efficient metal processing. These advanced machines offer optimal accuracy in machining various metals, supported by their sophisticated control systems. Their reliability and durability enable us to consistently deliver high quality even under demanding conditions.

Thanks to Fanuc technology, we significantly reduce processing times and achieve excellent surface finishes, enabling quick responses to market demands and efficient project implementation. These machines also contribute to energy efficiency and material optimization, increasing productivity and reducing operating costs. By using Fanuc EDM machines, Jungjohann demonstrates its commitment to technological leadership and highest quality standards in engraving technology.

1,000°C for maximum hardness

High-temperature furnaces

The innovative high-temperature furnace from Jungjohann reaches temperatures up to 1,150° Celsius, opening new possibilities in engraving technology and metal processing. This exceptional temperature capacity allows for the hardening and tempering of metals, which is especially significant in the manufacture of machine stamps. Furthermore, this high-temperature furnace is excellently suited for hardening powder metallurgical materials, which is increasingly important in modern manufacturing technology. The ability to provide high-quality and demanding engraving tools makes Jungjohann a valuable partner in the industry. With our high-temperature furnace, we offer a technological pinnacle that gives your products new possibilities and significantly enhances the efficiency and quality of your engraving results.

Available immediately – rapid implementation

In-house material warehouse

Jungjohann always maintains an extensive selection of materials in our own warehouse, allowing us to respond quickly and efficiently to our customers’ needs. This strategy ensures not only immediate availability of high-quality raw materials but also a significant reduction in lead times.

With our own material warehouse, we can adapt flexibly to short-term orders and special customer requests. This capability is particularly valuable in engraving and embossing technology, where tailored solutions are often required. Our customers benefit from this logistical strength through improved planning security and the ability to promptly respond to unexpected demands.

The constant availability of various materials not only enhances our production capacity but also supports our innovation by allowing us to quickly implement new products and processes. Customers of Jungjohann thus enjoy the advantage that their projects can be realized with the assurance of reliable and prompt material supply.

Engravings from Remscheid

Your benefits with Jungjohann

The direct line

Your contact with Jungjohann

As the managing director of Jungjohann Engraving Technology, I am your direct contact person. For questions, quotes, or information regarding our engraving techniques, please use the contact form. I ensure swift and precise responses to your inquiries.

Felix Opitz

Managing Director